PROGRAMMES

Find out about our Solutions

Sustainable Cleaning

Do you need help to meet the requirements of a label or do you want to turn to ecological and responsible cleaning solutions? Our experts are here to guide you.

We offer personalised follow-up according to your needs and targets.

Wastewater treatment

Do you have problems with bad odours, blocking or even overflowing? Is wastewater management a problem in your establishment? The treatment of your wastewater is a real problem that it is important to manage before it is too late.

Continue reading “Wastewater treatment”Biosafety

Are you experiencing recurrent hygiene problems or serious contamination on your production site? Frequent non-conformities, unstable microbiological trends, customer complaints or organoleptic problems (smell, taste), etc. This may indicate the presence of biofilm on your equipment.

Continue reading “Biosafety”PRODUCTS

ENZYBREW

ENZYBREW 10 is a tri-enzymatic mixture for the daily cleaning of your brewery equipment. This unique solution eliminates all encrusted organic residues present during beer production: plant fibres (hops, brewery residues), starch, caramelised sugars, etc. Ideal for cleaning filter plates, plate heat exchangers and boiling, fermentation and maturation tanks.

For the treatment of bacterial contamination, the Biorem® range ensures the detection, elimination and prevention of biofilm development.

APPLICATION

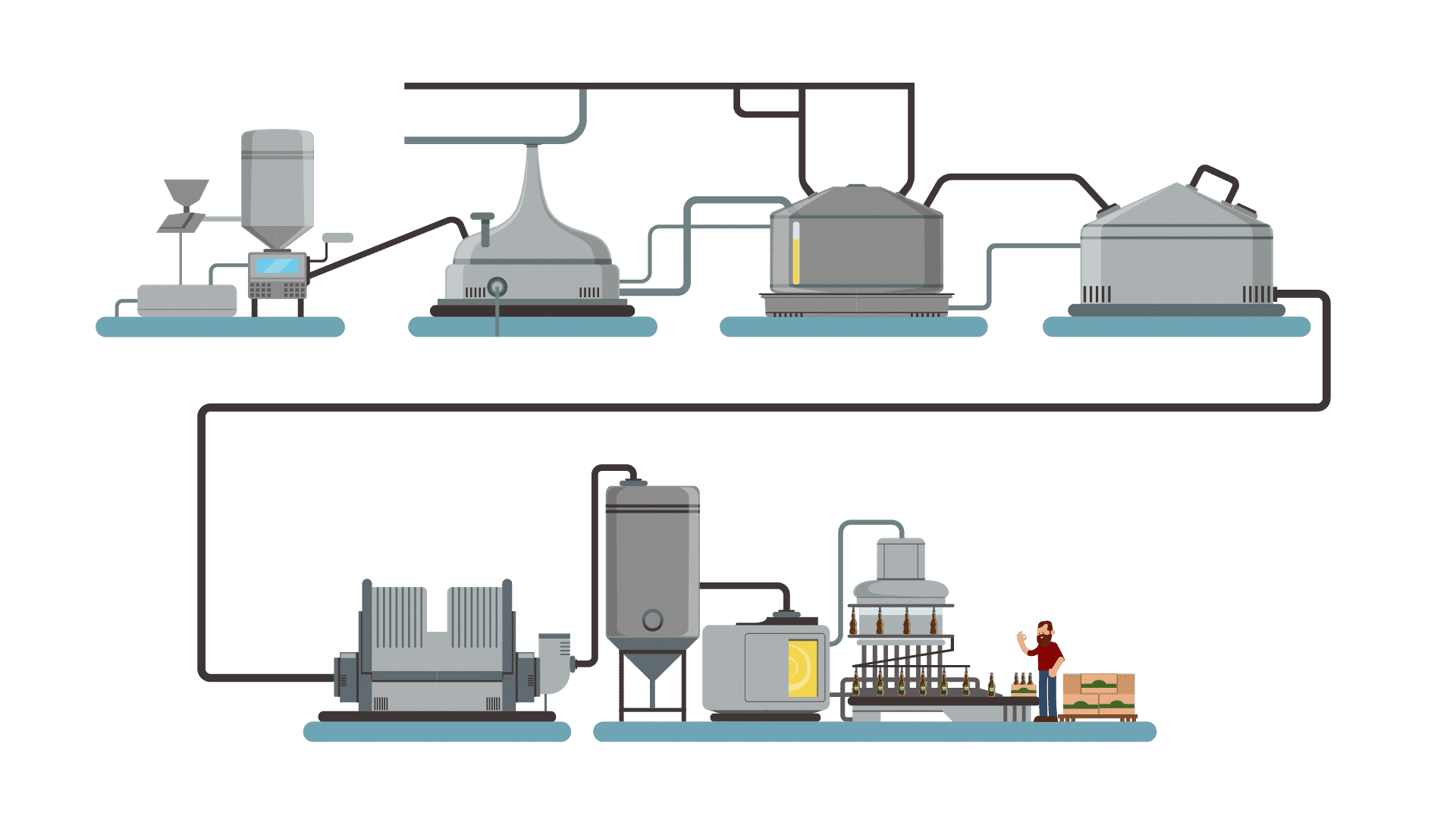

For use across your production line

The plate heat exchanger is the ultimate test for me. The results with Enzybrew 10 far outweighed my expectations. I stopped cleaning with caustic soda immediately!

Stéphane Vlaminck • Brasserie du Renard (BelgiUM)

SERVICES

Tailor-made support

Audit, Follow-up & Monitoring

Our experts monitor your cleaning processes to optimise your hygiene procedures and productivity

Continue reading “Audit, Follow-up & Monitoring”Training

The information and awareness of the personnel represent a fundamental pillar in the field of hygiene. An employee is efficient and reliable if he/she knows, understands and masters the rules of hygiene.

Continue reading “Training”

DID YOU KNOW?

Most beer spoilage bacteria are

Lactobacillus, Pediococcus, Pectinatus, Zymomonas, Megasphaera, etc., can develop a biofilm on various items of equipment (wort cooler, fermentation tanks, maturation tanks, etc.) and lead to serious beer contamination: off-tastes, pH and fermentation problems, recalls, etc.